T-slot aluminium extrusion profiles have revolutionized the way industries approach the design and construction of various systems and frameworks. Their inherent versatility, coupled with ease of use and robust performance, has made them indispensable in a myriad of industrial applications. This passage delves into the multifaceted utility of T-slot aluminium extrusion profiles, exploring their benefits, applications, and the reasons behind their widespread adoption in the industrial sector.

Understanding T-slot Aluminium Extrusion Profiles

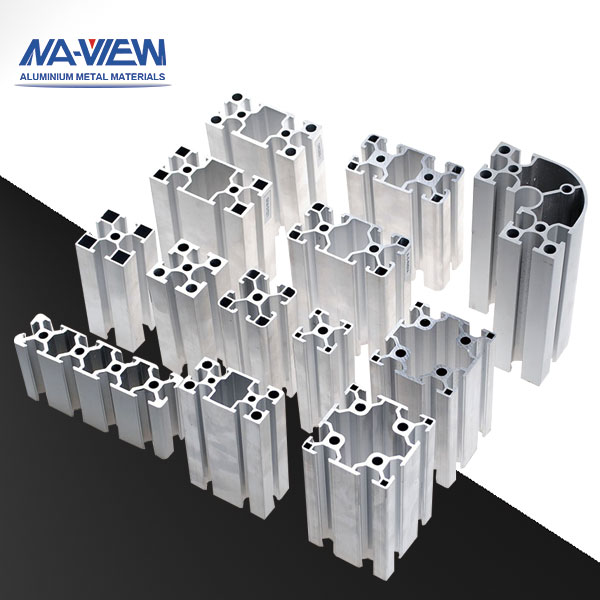

T-slot aluminium extrusion profiles are engineered components characterized by a T-shaped slot that runs along their length. This slot allows for the easy insertion and secure attachment of various accessories and connectors, facilitating the creation of customizable structures. The extrusions are typically made from high-quality aluminium alloys, which offer a blend of strength, lightweight, and corrosion resistance, making them ideal for demanding industrial environments.

Benefits of T-slot Aluminium Extrusion Profiles

The benefits of T-slot aluminium extrusion profiles are numerous, contributing to their popularity in industrial applications:

1. Modularity and Flexibility: The primary advantage of T-slot profiles is their modularity. They allow for the construction of bespoke structures that can be easily modified, expanded, or reconfigured as needs change. This flexibility is particularly valuable in dynamic industrial settings where adaptability is crucial.

2. Ease of Assembly: T-slot profiles can be assembled with simple tools, eliminating the need for specialized equipment or skilled labor. Components are typically fastened together using standard connectors, bolts, and brackets, streamlining the assembly process and reducing construction time.

3. Strength and Durability: Despite their lightweight nature, T-slot aluminium extrusions offer excellent strength and durability. They can support substantial loads and withstand harsh industrial conditions, ensuring the longevity and reliability of the structures built with them.

4. Cost-Effectiveness: The ease of assembly and reusability of T-slot profiles translate into cost savings. Structures can be dismantled and reassembled with minimal effort, reducing the need for new materials and labor for modifications or repairs.

5. Customization: T-slot profiles come in various sizes, shapes, and finishes, allowing for a high degree of customization. This enables industries to tailor their designs to specific requirements, ensuring optimal performance and efficiency.

Industrial Applications of T-slot Aluminium Extrusion Profiles

The versatility of T-slot aluminium extrusion profiles is evident in their wide range of applications across different industrial sectors:

1. Machine Frames and Enclosures: T-slot profiles are commonly used to build machine frames and enclosures. Their ability to support heavy equipment while providing easy access for maintenance and adjustments makes them ideal for this purpose. The modularity of the profiles also allows for the integration of safety guards, control panels, and other components.

2. Workstations and Workbenches: Industrial workstations and workbenches often utilize T-slot profiles due to their adaptability. These structures can be customized with shelves, drawers, lighting, and ergonomic features to create efficient and comfortable work environments. The profiles’ reconfigurability ensures that workstations can evolve with changing tasks and workflows.

3. Automation and Robotics: In the field of automation and robotics, T-slot aluminium extrusions are used to construct robot frames, conveyor systems, and automated assembly lines. Their precision and stability are crucial for ensuring the accurate operation of automated systems. Additionally, the profiles can be easily modified to accommodate new equipment or process changes.

4. Material Handling and Storage: T-slot profiles are used to create custom racks, carts, and shelving units for material handling and storage. These structures can be designed to optimize space utilization and improve accessibility, enhancing overall efficiency in industrial facilities.

5. Test and Measurement Equipment: The adaptability of T-slot profiles makes them ideal for building test rigs and measurement equipment. Industries such as aerospace, automotive, and electronics rely on these structures to support precise testing and calibration activities. The profiles’ modular nature allows for quick adjustments and reconfiguration of test setups.

6. Cleanroom and Laboratory Environments: In cleanroom and laboratory settings, T-slot aluminium extrusions are used to construct frames for equipment and enclosures that maintain controlled environments. Their non-corrosive properties and ease of cleaning make them suitable for applications where hygiene and contamination control are paramount.

Technological Advancements and Future Trends

The continuous evolution of T-slot aluminium extrusion technology is opening new possibilities for industrial applications. Advances in materials science are leading to the development of stronger and more durable aluminium alloys, enhancing the performance of T-slot profiles. Additionally, innovations in extrusion processes are allowing for more complex and precise profile designs, expanding the range of potential uses.

Integration with smart technologies is another emerging trend. T-slot profiles are being equipped with sensors and connectivity features to support Industry 4.0 initiatives, enabling real-time monitoring and control of industrial systems. This integration enhances operational efficiency, reduces downtime, and facilitates predictive maintenance.

Conclusion

The versatility of T-slot aluminium extrusion profiles makes them a cornerstone of modern industrial applications. Their modularity, ease of assembly, strength, and customization capabilities provide industries with the flexibility to design and build structures that meet specific needs and adapt to changing requirements. As technological advancements continue to drive innovation, the utility of T-slot aluminium extrusions will only increase, solidifying their role as a vital component in the industrial landscape.