In the ever-evolving field of modern architecture, materials play a pivotal role in defining the aesthetic and functional qualities of structures. Among these materials, aluminium extrusion profiles have emerged as a key component, offering a blend of versatility, durability, and sustainability that is well-suited to contemporary architectural needs. This passage explores the significance of aluminium extrusion profiles in modern architecture, highlighting their benefits, applications, and the technological advancements that have propelled their widespread adoption.

Versatility and Design Flexibility

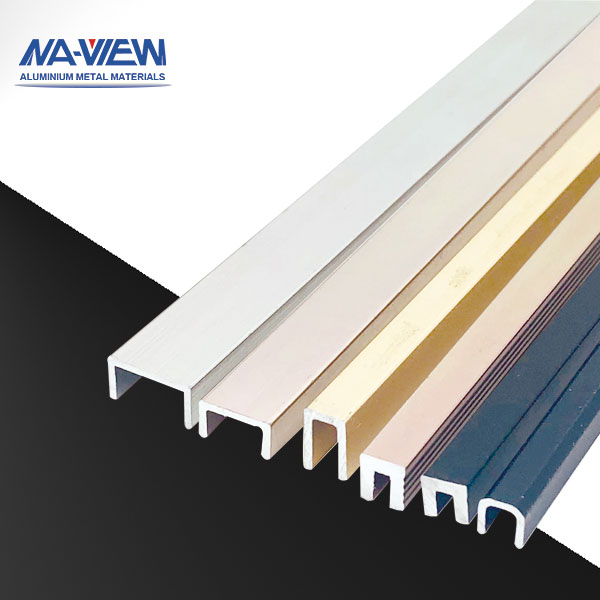

One of the primary advantages of aluminium extrusion profiles is their exceptional versatility. The extrusion process allows for the creation of complex cross-sectional shapes that can be tailored to specific architectural requirements. This flexibility in design enables architects to experiment with innovative forms and intricate details that would be challenging or impossible to achieve with other materials. From sleek curtain walls to intricate window frames, aluminium extrusion profiles provide the freedom to bring creative visions to life.

Aluminium’s malleability also allows for the production of lightweight yet strong structural components. This is particularly beneficial in modern architecture, where there is a growing emphasis on creating structures that are both visually striking and functionally efficient. The ability to design thin, elegant profiles without compromising on strength supports the trend towards minimalistic and streamlined architectural aesthetics.

Durability and Low Maintenance

Durability is another critical factor that makes aluminium extrusion profiles ideal for architectural applications. Aluminium is naturally resistant to corrosion, which ensures longevity and reduces the need for frequent maintenance. This is especially important in structures exposed to harsh weather conditions or coastal environments where other materials might deteriorate more rapidly. The long lifespan of aluminium components contributes to the sustainability of buildings by minimizing the need for replacements and repairs.

In addition to its inherent corrosion resistance, aluminium can be further enhanced through various surface treatments such as anodizing and powder coating. These treatments not only improve the material’s aesthetic appeal but also provide additional protection against environmental factors, further extending the life of the architectural elements.

Sustainability and Environmental Benefits

As sustainability becomes an increasingly important consideration in architecture, aluminium extrusion profiles stand out due to their environmental benefits. Aluminium is a highly recyclable material, and the recycling process requires only a fraction of the energy needed to produce new aluminium from raw ore. This makes it an eco-friendly choice that supports the reduction of the carbon footprint associated with building construction.

Moreover, the use of aluminium extrusion profiles can contribute to the overall energy efficiency of buildings. Aluminium’s excellent thermal conductivity properties allow for the design of profiles that incorporate thermal breaks, reducing heat transfer and enhancing the insulation of buildings. This can lead to significant energy savings in heating and cooling, aligning with the goals of sustainable architecture.

Technological Advancements

The advancements in extrusion technology have significantly expanded the possibilities of using aluminium profiles in modern architecture. Precision engineering and computer-aided design (CAD) have enabled the production of highly accurate and intricate profiles that meet exacting specifications. This level of precision is crucial for ensuring the seamless integration of aluminium components into architectural designs.

Additionally, innovations in alloy development have led to the creation of aluminium alloys with enhanced mechanical properties, such as increased strength and improved formability. These advanced alloys allow for the production of profiles that can withstand greater loads and stress, making them suitable for a wider range of structural applications.

Applications in Modern Architecture

The applications of aluminium extrusion profiles in modern architecture are vast and varied. One of the most prominent uses is in the construction of curtain wall systems. These systems, which form the exterior envelope of buildings, benefit from aluminium’s lightweight nature and structural strength. Aluminium curtain walls can span large areas with minimal support, allowing for expansive glass facades that maximize natural light and offer unobstructed views.

Aluminium extrusion profiles are also commonly used in window and door frames. Their slim yet sturdy designs enable larger openings and more glass, contributing to the open and airy feel of modern buildings. Additionally, the ability to incorporate thermal breaks in these profiles enhances the energy efficiency of the fenestration systems.

Beyond these common applications, aluminium extrusion profiles are found in a variety of other architectural elements, including balustrades, louvers, sunshades, and structural glazing systems. Their adaptability and customizability make them suitable for both standard and bespoke architectural solutions.

Conclusion

In conclusion, aluminium extrusion profiles have become indispensable in modern architecture due to their versatility, durability, and sustainability. The ability to create custom shapes and lightweight structures, coupled with the material’s resistance to corrosion and environmental benefits, makes aluminium an ideal choice for contemporary architectural designs.

Technological advancements continue to push the boundaries of what can be achieved with aluminium extrusion profiles, ensuring their prominent role in the future of architecture. As architects strive to balance aesthetics, functionality, and environmental responsibility, manufacturers like Naview will undoubtedly remain at the forefront of material selection, driving innovation and quality in the industry.