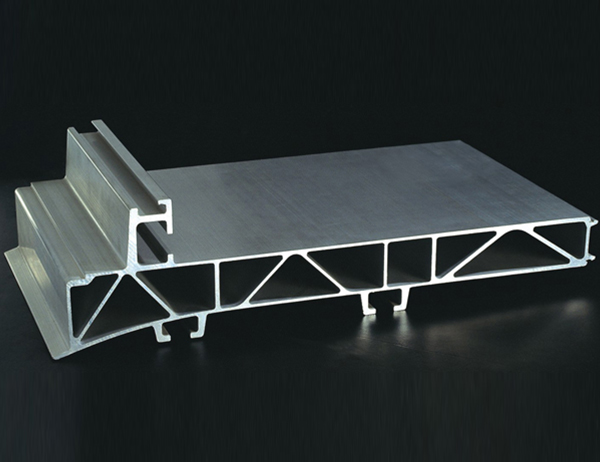

Custom aluminum extrusion profiles offer a myriad of advantages, making them a preferred choice for architects, designers, and manufacturers seeking versatile and efficient solutions. These profiles are crafted through a process known as aluminum extrusion, where a billet of aluminum is forced through a die to create a specific cross-sectional shape. This method allows for the creation of complex profiles that are not easily achievable with other manufacturing techniques, providing designers with unparalleled flexibility and customization options.

Versatility and Customization

The versatility of custom aluminum extrusion profiles is unmatched. They can be created in virtually any shape or size, making them suitable for a wide range of applications. Whether you require a simple square profile or a complex, multi-chambered profile, custom aluminum extrusion can fulfill your needs with precision and accuracy.

Moreover, custom aluminum extrusion profiles can be tailored to meet the specific requirements of your project. This includes selecting the alloy and temper of the aluminum, as well as choosing the surface finish and tolerances. This level of customization ensures that you receive a profile that is perfectly suited to your project's unique specifications. Gold Apple, professional aluminum profile supplier, specializes in crafting custom aluminum extrusion profiles that meet the highest standards of quality and performance.

Strength and Durability

Aluminum extrusion profiles are renowned for their strength and durability. Aluminum is inherently strong, and the extrusion process further enhances these properties by aligning the aluminum molecules in a uniform pattern. This results in a profile that can withstand heavy loads and harsh environments, making it ideal for use in construction and industrial applications where durability is paramount.

Lightweight and Corrosion-Resistant

Despite their strength, custom aluminum extrusion profiles are lightweight, making them easy to transport and install. This is especially beneficial in construction projects, where reducing weight can lead to cost savings and easier installation processes.

Additionally, aluminum is naturally corrosion-resistant, making custom aluminum extrusion profiles ideal for outdoor applications. Whether used in architectural facades, marine applications, or automotive components, aluminum extrusion profiles can withstand exposure to the elements without deteriorating, ensuring longevity and reliability.

Energy Efficiency and Sustainability

Custom aluminum extrusion profiles are also known for their energy efficiency. Aluminum is a highly conductive material, meaning that it can quickly and efficiently transfer heat and cold. This can lead to energy savings in heating and cooling applications, making aluminum extrusion profiles an environmentally friendly choice.

Furthermore, aluminum is one of the most recyclable materials on the planet, with nearly 75% of all aluminum ever produced still in use today. This makes custom aluminum extrusion profiles a sustainable choice for environmentally conscious projects, as they can be recycled and repurposed with minimal impact on the environment.

Applications of Custom Aluminum Extrusion Profiles

Custom aluminum extrusion profiles have a wide range of applications across various industries. In the construction industry, they are used to create architectural facades, window and door frames, and structural components. Their strength, durability, and aesthetic appeal make them ideal for use in modern building design, where they can enhance the overall look and feel of a structure.

In the automotive industry, custom aluminum extrusion profiles are used to create lightweight components that help improve fuel efficiency and reduce emissions. They are also used in the manufacturing of consumer electronics, where their lightweight and durable properties make them ideal for use in mobile devices, laptops, and other electronic products.

Conclusion

Custom aluminum extrusion profiles offer unparalleled versatility, strength, and durability, making them a superior choice for a wide range of applications. Their lightweight nature, corrosion resistance, and energy efficiency make them an ideal choice for environmentally conscious projects seeking innovative and sustainable solutions. Whether you're designing a modern building, constructing industrial machinery, or creating consumer electronics, custom aluminum extrusion profiles are sure to meet your needs with efficiency and precision.