Aluminium profile extrusion has long been a staple in the manufacturing industry, offering a versatile and cost-effective solution for creating complex shapes and designs. In recent years, however, innovations in extrusion technology have pushed the boundaries of what is possible, allowing manufacturers to meet the demands of modern design in ways that were previously unimaginable. This passage explores some of the key innovations in aluminium profile extrusion and how they are shaping the future of design.

Advanced Design Software

One of the most significant innovations in aluminium profile extrusion is the development of advanced design software. These software programs allow designers to create complex profiles with precision and accuracy, enabling them to push the boundaries of traditional extrusion techniques.

By using these software programs, designers can create profiles that are not only visually striking but also highly functional, meeting the specific requirements of modern design.

Customized Die Design

Another innovation in aluminium profile extrusion is the development of customized die design. Traditional extrusion dies were limited in their ability to create complex shapes, often resulting in profiles that were simple and utilitarian.

With customized die design, however, manufacturers can create profiles that are highly complex and intricate, allowing for a greater degree of design freedom. This has opened up new possibilities for designers, enabling them to create profiles that are both aesthetically pleasing and functional.

Multi-Axis Extrusion

Multi-axis extrusion is another innovation that is revolutionizing the world of aluminium profile extrusion design. This technique allows manufacturers to extrude profiles in multiple directions simultaneously, creating profiles that are highly complex and geometrically challenging.

This technique is particularly useful for creating profiles with irregular shapes or profiles that require precise tolerances. By using multi-axis extrusion, manufacturers can create profiles that are truly unique, meeting the demands of modern design.

Improved Surface Finishes

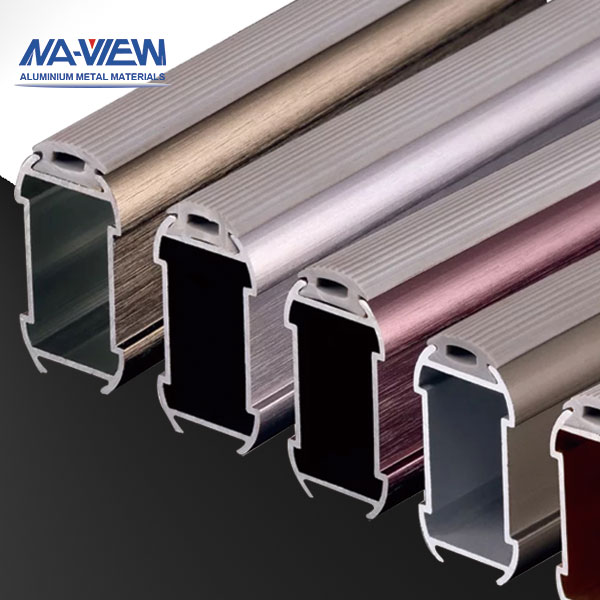

In addition to advancements in extrusion technology, there have also been significant improvements in surface finishes for aluminium profiles. Traditionally, extruded aluminium profiles had a rough and uneven surface finish, making them unsuitable for many applications.

However, with advancements in surface finishing techniques, manufacturers can now produce profiles with a smooth and uniform finish, making them ideal for a wide range of applications, including architectural and automotive design.

Integration of Additive Manufacturing

One of the most exciting innovations in aluminium profile extrusion is the integration of additive manufacturing techniques. Additive manufacturing, also known as 3D printing, allows manufacturers to create highly complex shapes and designs that would be impossible to achieve with traditional extrusion techniques.

By integrating additive manufacturing into the extrusion process, manufacturers can create profiles that are highly customized and tailored to meet the specific requirements of modern design.

Sustainability and Recycling

Finally, there has been a growing focus on sustainability and recycling in aluminium profile extrusion. Manufacturers are increasingly using recycled aluminium in their extrusion processes, reducing the environmental impact of production.

Additionally, there has been a push towards designing profiles that are more energy-efficient, using less material and energy to produce. By focusing on sustainability and recycling, manufacturers are able to meet the demands of modern design while reducing their environmental footprint.

Conclusion

In conclusion, the innovations in aluminium profile extrusion are revolutionizing the world of design. From advanced design software to multi-axis extrusion techniques, these innovations are allowing manufacturers to create profiles that are more complex, functional, and sustainable than ever before.

As the demand for innovative design solutions continues to grow, it is clear that aluminium profile extrusion will play a crucial role in shaping the future of design.