Aluminium heatsink extrusions play a crucial role in thermal management, dissipating heat generated by electronic components to ensure optimal performance and longevity. Selecting the right heatsink extrusion for your application involves considering various factors, including design requirements, thermal performance, and cost-effectiveness. This passage explores the key considerations in selecting the right aluminium heatsink extrusion for your application.

Understanding Aluminium Profile Extrusion for Heatsinks

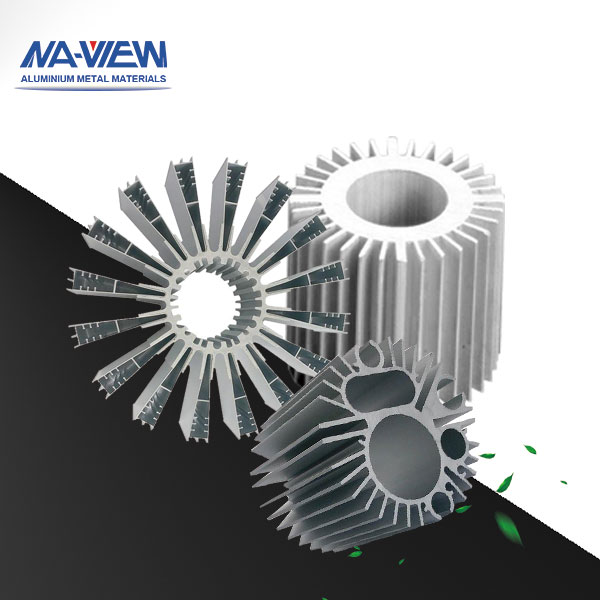

Aluminium profile extrusion is a manufacturing process that produces complex cross-sectional shapes by forcing aluminium through a die. Heatsink extrusions are designed with fins or other structures to increase surface area, facilitating heat dissipation. These extrusions can be customized to meet specific design requirements, making them suitable for a wide range of applications.

Factors to Consider

1. Thermal Performance: The primary function of a heatsink is to dissipate heat efficiently. When selecting a heatsink extrusion, consider the thermal conductivity of the aluminium alloy used, as well as the design of the fins and overall surface area. Thicker fins and larger surface areas typically offer better thermal performance.

2. Size and Form Factor: Heatsink extrusions come in various sizes and shapes to accommodate different applications. Consider the available space and airflow in your system when selecting the size and form factor of the heatsink extrusion.

3. Material and Finish: The choice of material and finish can affect the heatsink's thermal performance and durability. Aluminium alloys with high thermal conductivity, such as 6000 series alloys, are commonly used. Anodized finishes can improve corrosion resistance and enhance the heatsink's appearance.

4. Mounting Options: Heatsink extrusions can be mounted using various methods, including adhesive tapes, screws, or clips. Consider the mounting options available and choose one that is suitable for your application.

5. Cost-Effectiveness: While thermal performance is crucial, it's also essential to consider the cost-effectiveness of the heatsink extrusion. Balance the performance requirements with the cost of the extrusion to ensure that it meets your budget constraints.

Customization Options

One of the key advantages of aluminium profile extrusion for heatsinks is the ability to customize the design to meet specific requirements. Manufacturers can create heatsink extrusions with varying fin heights, thicknesses, and fin densities to achieve the desired thermal performance. Additionally, the extrusions can be cut to custom lengths and machined to accommodate specific mounting or interface requirements.

Application Considerations

When selecting a heatsink extrusion, consider the specific requirements of your application. For example, if your application requires a compact heatsink with limited space, you may opt for a design with closely spaced fins to maximize surface area. On the other hand, if space is not a constraint, a larger heatsink with thicker fins may be more suitable.

Conclusion

Selecting the right aluminium heatsink extrusion for your application involves considering various factors, including thermal performance, size, material, mounting options, and cost-effectiveness. Aluminium profile extrusion offers a versatile and customizable solution for thermal management, allowing manufacturers to create heatsinks that meet the specific requirements of their applications. By carefully considering these factors and leveraging the customization options available, you can select a heatsink extrusion that meets your thermal management needs effectively.