Industrial aluminium profiles have become an integral component in a wide range of sectors, thanks to their versatility, durability, and cost-effectiveness. Their ability to be easily customized and assembled into complex structures makes them ideal for a myriad of applications across industries.

This passage explores the diverse uses of industrial aluminium profiles in sectors such as manufacturing, construction, transportation, and more, highlighting their key advantages and innovative applications.

Manufacturing Sector

In the manufacturing sector, industrial aluminium profiles are widely used for machine frames, workstations, conveyors, and material handling systems. Their modularity allows for quick and easy assembly, modification, and reconfiguration, making them ideal for lean manufacturing practices. Aluminium profiles are also used for safety guarding, providing a sturdy and customizable barrier around machinery to protect workers and prevent accidents.

Construction Sector

In the construction sector, industrial aluminium profiles are used for structural framing, curtain walls, windows, doors, and roofing systems. The lightweight yet strong properties of aluminium make it an ideal material for constructing high-rise buildings and large structures. Aluminium profiles are also used for interior design elements such as partitions, railings, and staircases, providing a modern and sleek aesthetic.

Transportation Sector

In the transportation sector, industrial aluminium profiles are used for the construction of lightweight and fuel-efficient vehicles. Aluminium profiles are used in the fabrication of vehicle frames, chassis components, and body panels, helping to reduce overall vehicle weight and improve fuel efficiency. Aluminium profiles are also used in the construction of trailers, truck bodies, and railway cars, providing strength and durability while reducing weight.

Aerospace Sector

In the aerospace sector, industrial aluminium profiles are used for the construction of aircraft frames, wings, and fuselage components. The high strength-to-weight ratio of aluminium makes it an ideal material for aerospace applications, where weight savings are critical for fuel efficiency and performance. Aluminium profiles are also used for interior components such as seating frames, overhead bins, and cabin partitions.

Electronics Sector

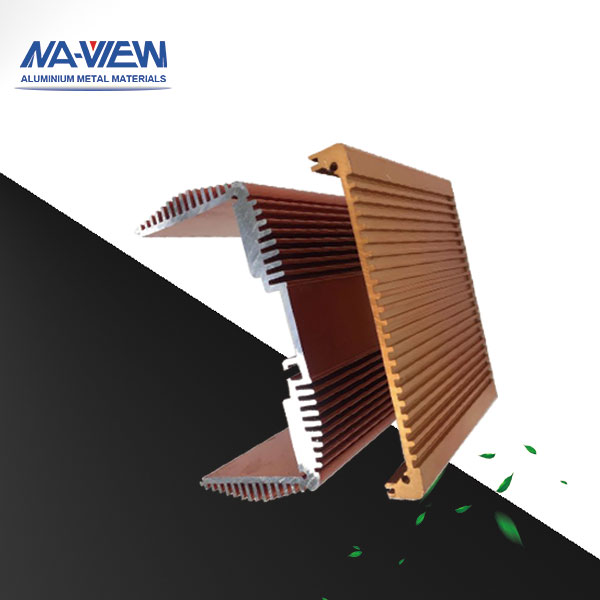

In the electronics sector, industrial aluminium profiles are used for the construction of enclosures, racks, and cabinets for electronic equipment. Aluminium profiles provide electromagnetic shielding and heat dissipation properties, ensuring the reliable operation of sensitive electronic components. Aluminium profiles are also used for mounting brackets, heat sinks, and other components that require precision and stability.

Renewable Energy Sector

In the renewable energy sector, industrial aluminium profiles are used for the construction of solar panel frames, wind turbine towers, and support structures. The corrosion-resistant properties of aluminium make it ideal for outdoor applications in harsh environments. Aluminium profiles are also used for mounting systems, tracking systems, and other components that require strength and durability.

Other Sectors

Industrial aluminium profiles are also used in a variety of other sectors, including furniture manufacturing, retail displays, exhibition stands, and lighting fixtures. The versatility of aluminium profiles allows for endless possibilities in design and functionality, making them a preferred choice for many applications.

Conclusion

Industrial aluminium profiles have become a staple in various sectors, thanks to their versatility, durability, and cost-effectiveness. From manufacturing and construction to transportation, aerospace, electronics, and renewable energy, aluminium profiles play a vital role in shaping modern industries. As technology advances and new applications emerge, the demand for aluminium profiles is expected to continue growing, driving innovation and efficiency across sectors.

Manufacturers like Naview, a leading producer of high-quality industrial aluminium profiles, play a crucial role in meeting the diverse needs of industries worldwide. With a focus on quality, innovation, and customer satisfaction, Naview continues to push the boundaries of what is possible with aluminium profiles, ensuring that they remain a cornerstone of modern industrial applications.