Aluminium extrusion is a versatile process that allows for the creation of a wide range of profiles used in various industries. These profiles differ in shape, size, and complexity, making them suitable for different applications. In this comprehensive guide, we will explore the different types of aluminium extrusion profiles, their characteristics, and common applications.

Standard Profiles

Solid Profiles

Solid profiles are the most basic type of aluminium extrusion profiles. They are solid throughout and are often used in applications where strength and rigidity are required. Solid profiles can be square, rectangular, or round in shape and are commonly used in construction, automotive, and manufacturing industries.

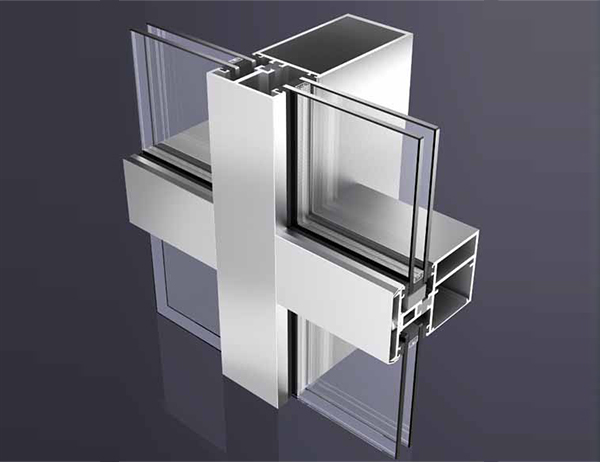

Hollow Profiles

Hollow profiles have a hollow interior, which reduces weight while maintaining strength. These profiles are often used in applications where weight is a concern, such as in the aerospace and automotive industries. Hollow profiles can be square, rectangular, or round and are versatile enough to be used in a wide range of applications.

Structural Profiles

T-Slot Profiles

T-slot profiles have a T-shaped slot along one or more sides, allowing for easy assembly using T-slot nuts and bolts. These profiles are commonly used in applications where modularity and flexibility are required, such as in the construction of workstations, shelving units, and machine frames.

I-Beam Profiles

I-beam profiles have a shape similar to the letter "I" and are used in applications where strength and rigidity are paramount. These profiles are commonly used in the construction of bridges, buildings, and other structures where heavy loads need to be supported.

L-Shaped Profiles

L-shaped profiles have an L-shaped cross-section and are commonly used as brackets, supports, and framing elements. These profiles are versatile and can be used in a wide range of applications where a strong, rigid structure is required.

Custom Profiles

Complex Profiles

Complex profiles are custom-designed profiles that have a unique shape and geometry. These profiles are often used in applications where standard profiles cannot meet the requirements. Complex profiles can be used in a wide range of industries, including automotive, aerospace, and electronics.

Heat Sink Profiles

Heat sink profiles are designed to dissipate heat efficiently and are commonly used in electronic devices such as computers and LED lights. These profiles have a complex geometry with fins and channels that increase the surface area, allowing for better heat dissipation.

Special Profiles

Telescopic Profiles

Telescopic profiles consist of two or more nested sections that can slide into each other, allowing for adjustable length. These profiles are commonly used in applications where adjustable length is required, such as in antenna masts and furniture legs.

Slotted Profiles

Slotted profiles have slots along one or more sides, allowing for easy attachment of accessories and components. These profiles are commonly used in applications where flexibility and modularity are required, such as in the construction of exhibition stands and retail displays.

Conclusion

Aluminium extrusion profiles come in a wide range of types, each with its own characteristics and applications. Whether you need a standard solid profile for a construction project or a custom complex profile for a specialized application, Gold Apple always has an aluminium extrusion profile type to meet your needs. Understanding the different types of aluminium extrusion profiles can help you choose the right profile for your project and ensure its success.